SEMI-AUTOMATIC LINES / ECO

DESCRIPTION

All double-glazing production lines adopt a modular concept and can therefore can be adapted to the needs of the individual customer.

Made up of 2 m modules the glass is transported via a system of anti-cut rollers with frictioned components to increase operator safety.

The washing machine body is in powder-coated stainless steel and is 1.6 meters long. All components in contact with water are corrosion resistant and equipped with 4 brushes of 80 mm diameter with steel shafts and aluminum supports.

The water management group is made up of three washing zones with tanks, pumps, filters and internal parts in stainless steel. Thanks to the shape of the tanks, water consumption has been reduced to a bare minimum reusing wastewater from one sector to another.

The thermostat-controlled heating system is standard over the entire range.

The output module is equipped with a new continuous LED light system to allow better control of the washing quality.

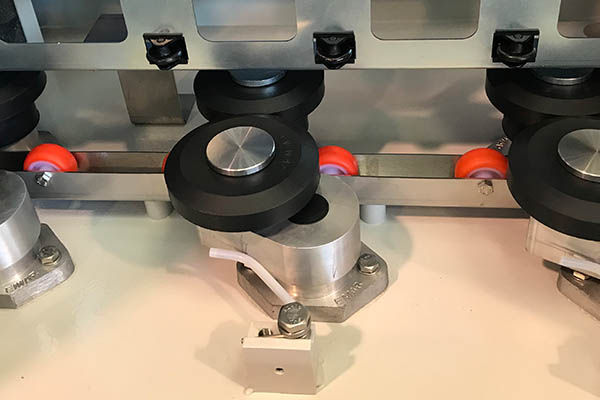

The motorised assembly is made up of double anti-cut rubber rollers mounted on friction systems. The transport is managed by an inverter which allows the processing speed to be increased during the movement of the glass, reducing waiting time to a minimum. Thanks to the LED light system it is possible to identify any imperfections on the glass.

A laser sensor guarantees high positioning precision of the profile. The pneumatic movement pistons are controlled by oil-filled clearance adjusters and managed by sensors that read the thickness of the glass, to allow the operator to position the groove without any adjustment while working on different glass thicknesses.

The 1 m roller press is equipped with anti-cut friction supports and moves via pneumatic pistons in material treated with bushings.

The machine can be adjusted by the operator to vary the pressing thrust.

The fixed exit is made up of a 3 m module with the glass being transported via a system of anti-cut rollers mounted on frictioned components to increase operator safety.

The machine has been set up for connection to other work modules.

TECHNICAL SPECIFICATIONS

Power supply

400 Vac Three-phase + Neutral 50 Hz

Total consumption

15 Kw 400 Vac 50 Hz

Fan motor

4 Kw 400 Vac Three-phase 50 Hz

Hot water resistance

1,5 Kw 400 Vac 50 Hz

Washing brushes

4 standard

(optional LOW-E)

Washing zone

2 separate zones with ECO WATER system

Washable glass measurements

Min 350 x 250h mm approx.

Max 2000 x 1500h (OPEN TOP)

Washable thickness

From 3 to 14 mm

(optional up to 20 mm)

Panel press thickness

50 mm approx.

Work direction

From left to right

(optional from right to left)

Working speed

4 m/minute

Work surface

600 mm approx.

Height

2600 mm approx.

Length

12,5 mt approx.

Width

1200 mm approx.

Weight

3000 Kg approx.

We recommend water supplied to the washing machine has the following characteristics:

Conductivity = less than 10 uS (microsiemens)

Hardness total = less than 5° F (French degrees)

Salt content = less than 5 mg/L

Chloride = less than 5 mg/L

Iron = less than 0,05 ppm

Torbidity = less than 0,5 ft

NB: The results of the window washing may be compromised if the water values are higher than the above recommended amounts. Upon request we can provide equipment for cleaning the water.

FEATURES

WATER RECOVERY

Water is a precious resource - the washing system is designed for a double reuse of water, avoiding unnecessary waste while maintaining optimal quality at the end of the process.

LONG-LASTING

Attention to durability over time is synonymous with quality - all parts of the machine in contact with water are made of powder-coated stainless steel, brush supports and tows in aluminium, pipes in stainless steel, and brass spray nozzles.

SAFE TRANSPORTATION

The safety of the operator is fundamental, but the glass must be moved for processing. The system adopted allows the glass to be blocked at any time with the rollers moving. All this thanks to an innovative type of transportation.

EASY MAINTENANCE

Thanks to the type of sector construction, maintenance and cleaning are convenient, easy and quick.

PLUG IN COMMUNICATION

All line connections are modular with special plugs and sockets dedicated to strength commands or the control of digital communication signals. The line, as standard, has been set up to work with other work modules from the sealing robot, warehouse transfer or tilting table.

DOUBLE OR TRIPLE GLASS

Thanks to a simple pedal it is possible to define the type of production, double or triple glass.

LASER PRECISION

The manual component of the line is in the assembly module where the operator places the profile. It is therefore essential to give all the references to the operator quickly and precisely. Thanks to the laser reading system it is possible to have high positioning precision and therefore reduce processing times.

SIMPLE AND RELIABLE

The assembly guarantees perfect positioning of the profile bar through this new system created from a mix of pneumatics and hydraulics.

VULKOLLAN® ROLLER

Vulkollan® is a polyurethane renowned for its exceptional resistance to dynamic stress and abrasion, laceration and cuts. This material guarantees long life over time.

CONTROLS AND ADJUSTMENTS

All controls are situated in the front part of the press and are simple and intuitive, allowing the operator to dynamically and precisely adjust all pressing parameters.

OPTIONALS

THICKNESSES UP TO 20 mm

Thanks to the self-aligning opening system it is possible to process glass thicknesses from 3 to 20 mm completely automatically.

TILTING EXIT

3 m tilting output module operated by a jack controlled by an electronic inverter. The module can be used both as a fixed warehouse and a sealing table.

MOTORISED ENTRY

The automation of the entrance guarantees safe movement of the glass in a completely autonomous manner.

LOW-E BRUSHES

These type of brushes have special bristles that allow the possibility of working with more delicate glass. They are complete components with a stainless-steel shaft.