VERTICAL WASHING MACHINES / STANDARD

DESCRIPTION

The double-glazing washing machines adopt a modular concept, therefore can be adapted to the needs of the individual customer.

The washing machine body is in powder-coated stainless steel and is 2.6 m long.

All components in contact with water are corrosion resistant.

The machine is equipped with 6 x 160 mm diameter brushes with steel shafts and aluminum supports.

The water management group is made up of three washing areas with tanks, pumps, filters and internal parts in stainless steel.

Thanks to the shape of the tanks, water consumption has been reduced to a bare minimum reusing wastewater from one sector to another.

The thermostat-controlled heating system is standard over the entire range

A fan for drying has been installed in an insulated box to reduce noise with a damper to manage the air flow allowing for greater energy saving during processing stops.

The working speed is adjustable and controlled exclusively by an electronic system that maintains the torque constant even with different weights.

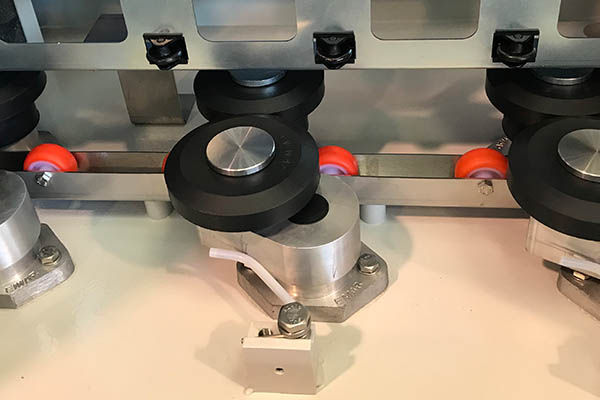

The motorised assembly is made up of double anti-cut rubber rollers mounted on friction systems. The transport is managed by an inverter which allows the processing speed to be increased during the movement of the glass, reducing waiting time to a minimum. Thanks to the LED light system it is possible to identify any imperfections on the glass.

The machine has been designed to be connected to other work modules.

TECHNICAL SPECIFICATIONS

Power supply

400 Vac Three-phase + Neutral 50 Hz

Total consumption

20 Kw 400 Vac 50 Hz

Hot water resistance

4.5 Kw 400 Vac Three-phase 50 Hz

Washing brushes

6 x 160 mm standard

(optional LOW-E)

Washing zones

3 separate zones with ECO WATER system

Glass washing measurements

Min 350 x 250h mm approx.

Max 2900 x 2000h mm

(Max 3800 x 2000h with 4 m modules)

Washing thickness

From 3 to 14 mm (optional up to 20 mm)

Work direction

From left to right

(optional from right to left)

Working speed

From 3 at 8 meters per minute

Work surface

600 mm approx.

Height

3000 mm approx.

Length

8600 mm approx.

Width

1500 mm approx.

Weight

2000 Kg approx.

We recommend water supplied to the washing machine has the following characteristics:

Conductivity = less than 10 uS (microsiemens)

Hardness total = less than 5° F (French degrees)

Salt content = less than 5 mg/L

Chloride = less than 5 mg/L

Iron = less than 0,05 ppm

Torbidity = less than 0,5 ft

NB: The results of the window washing may be compromised if the water values are higher than the above recommended amounts. Upon request we can provide equipment for cleaning the water.

FEATURES

WATER RECOVERY

Water is a precious resource - the washing system is designed for a double reuse of water, avoiding unnecessary waste while maintaining optimal quality at the end of the process.

LONG-LASTING

Attention to durability over time is synonymous with quality - All parts of the machine in contact with water are made of powder-coated stainless steel, brush supports and tows in aluminium, pipes in stainless steel, and brass spray nozzles.

ENERGY SAVING

Consumption is significantly reduced during processing thanks to a system which reduces motor consumption while maintaining the air flow active.

SAFE TRANSPORTATION

The safety of the operator is fundamental, but the glass must be moved for processing. The system adopted allows the glass to be blocked at any time with the rollers moving. All this thanks to an innovative type of transportation.

EASY MAINTENANCE

Thanks to the type of construction, maintenance and cleaning are convenient, easy and quick.

NOISE REDUCTION

A fan for drying has been installed in an insulated box to reduce noise with a damper to manage the air flow allowing for greater energy saving during processing stops. The cleanliness of the air is guaranteed by a removable filter.

OPTIONALS

THICKNESSES UP TO 20 mm

Thanks to the self-aligning opening system it is possible to process glass thicknesses from 3 to 20 mm completely automatically.

TILTING EXIT

3 m folding output module operated by a jack controlled by an electronic inverter. The module can be used both as a fixed storage and a sealing table.

LOW-E BRUSHES

These type of brushes have special bristles that allow you to work with more delicate glass. They are complete components with a stainless-steel shaft.