VERTICAL WASHING MACHINES / ECO

DESCRIPTION

Machine composed of an inlet with 2.000 mm idle Vulkollan rollers and a 2.000 mm motorized outlet with cut-resistant, accident-proof Vulkollan rollers and lights for inspecting the glass with safety limit switches.

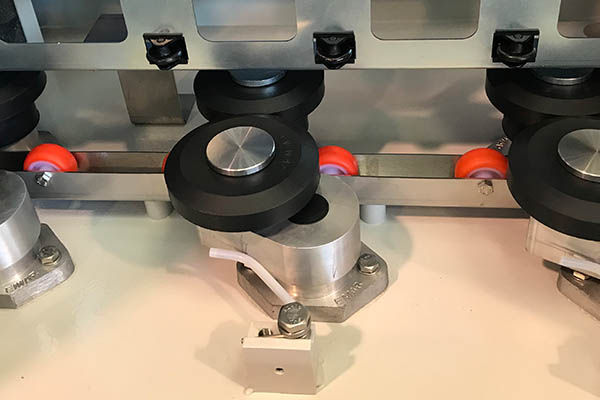

1.540 mm machine body with opening on the top side. Powder coated steel structure for greater resistance to corrosion. Washing unit with four 80 mm nylon cylindrical brushes (two front and two rear).

Two stainless steel water recycling tanks with two pumps.

Rinsing unit with possibility of connection to the demineralizer.

Thermal protection of motors and low voltage control circuit.

Two-blower drying system with high-pressure fan.

All controls in contact with the operator are in low safety voltage.

Protection against access to dangerous parts of the machine according to European regulations.

TECHNICAL SPECIFICATIONS

Power supply

400 Vac Three Phase + Neutral 50 Hz

Power consumption

7 Kw 400 Vac 50 Hz

Fan motor

4 Kw 400 Vac Three Phase 50 Hz

Hot water resistance

1,5 Kw 400 Vac Three Phase 50 Hz

Washing brushes

4 standard (optional LOW-E)

Washing areas

2 separate zones with ECO WATER system

Washable glass measurements

Min 300 x 250h mm approx.

Max 2000 x 2000h mm (OPEN TOP)

Washable thickness

Da 3 a 14 mm (optional fino a 20 mm)

Work direction

From left to right

(optional from right to left)

Work speed

4 meters per minute

Work surface

550 mm approx.

Height

2800 mm approx.

Length

7000 mm approx.

Width

1000 mm approx.

Weight

1050 Kg approx.

We recommend water supplied to the washing machine has the following characteristics:

Conductivity = less than 10 uS (microsiemens)

Hardness total = less than 5° F (French degrees)

Salt content = less than 5 mg/L

Chloride = less than 5 mg/L

Iron = less than 0,05 ppm

Torbidity = less than 0,5 ft

NB: The results of the window washing may be compromised if the water values are higher than the above recommended amounts. Upon request we can provide equipment for cleaning the water.

FEATURES

WATER RECOVERY

Water is a precious resource - the washing system is designed for a double reuse of water, avoiding unnecessary waste while maintaining optimal quality at the end of the process.

LONG-LASTING

Attention to durability over time is synonymous with quality - All parts of the machine in contact with water are made of powder-coated stainless steel, brush supports and tows in aluminium, pipes in stainless steel, and brass spray nozzles.

SAFE TRANSPORTATION

The safety of the operator is fundamental, but the glass must be moved for processing. The system adopted allows the glass to be blocked at any time with the rollers moving. All this thanks to an innovative type of transportation.

EASY MAINTENANCE

Thanks to the type of construction, maintenance and cleaning are convenient, easy and quick.

OPTIONALS

THICKNESSES UP TO 20 mm

Thanks to the self-aligning opening system it is possible to process glass thicknesses from 3 to 20 mm completely automatically.

MOTORIZED ENTRY

The automation of the entrance guarantees safe movement of the glass in a completely autonomous manner.

LOW-E BRUSHES

These type of brushes use special bristles that allow you to work with more delicate glass. They are complete components with a stainless-steel shaft.

FAN BOX

The box for the fan allows a notable reduction in noise and, via a filter, guarantees excellent air quality free of impurities.